In mid November I received an email requesting me to make a custom cabinet similar to one I had made recently and to specific dimensions. I put together an estimate that was to include shipping to the Washington DC area. Something new that I wanted to try was to make the stand completely glued up instead of a knock-down design. This would allow for a much nicer looking design without the extra material required to house the knock-down hardware. It would also incur extra shipping considerations.

In mid November I received an email requesting me to make a custom cabinet similar to one I had made recently and to specific dimensions. I put together an estimate that was to include shipping to the Washington DC area. Something new that I wanted to try was to make the stand completely glued up instead of a knock-down design. This would allow for a much nicer looking design without the extra material required to house the knock-down hardware. It would also incur extra shipping considerations.

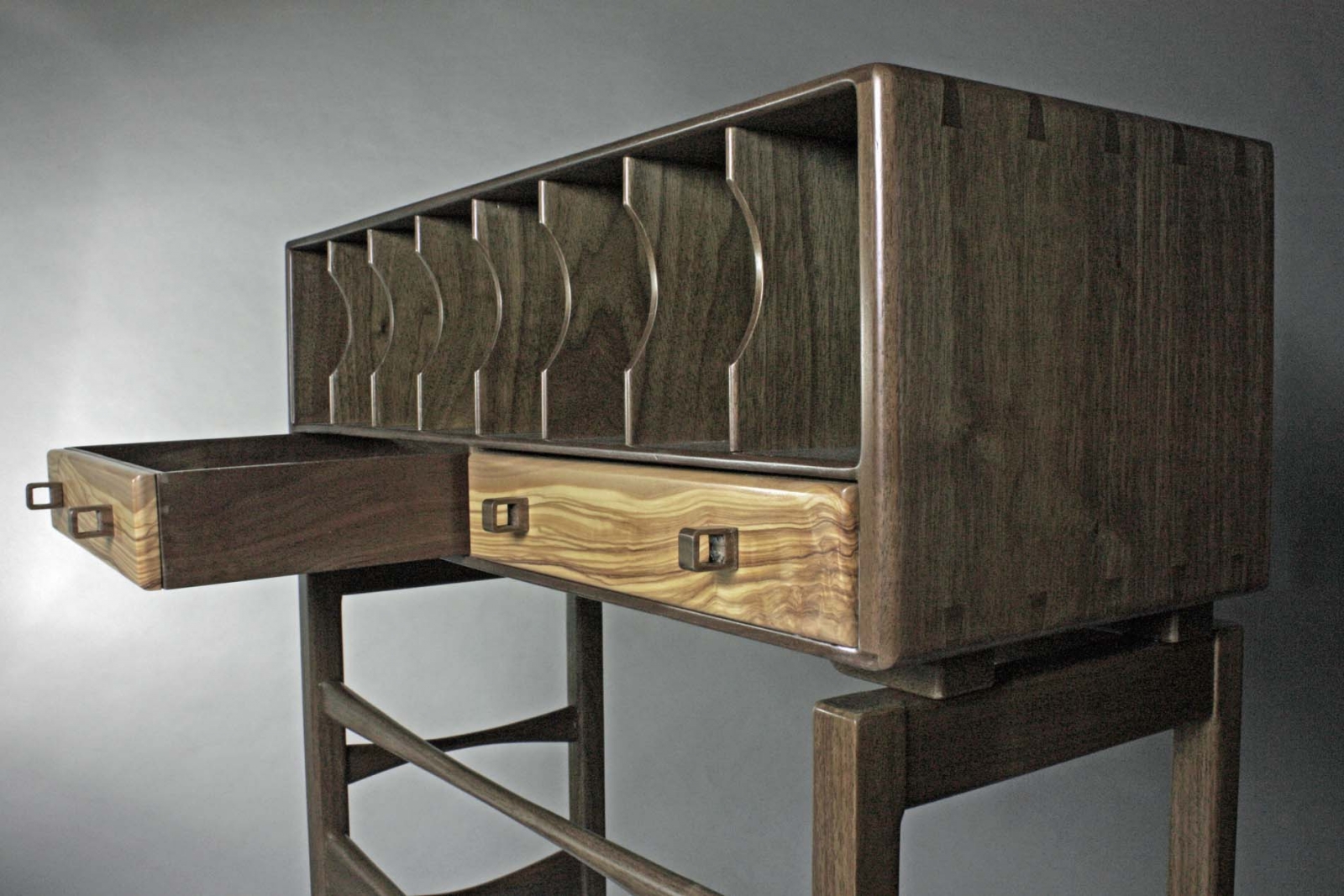

The design included olive wood drawer fronts. I had this large piece of olive wood that I purchased a couple years ago from Hearne Hardwoods for just such a project. Olive wood is quite expensive and often very checked (cracked). I schmoozed a single length from the plank to have a matching figure pattern across the 30 inch width of drawers. It came out well. The drawer pulls are also made especially for this cabinet.

The design included olive wood drawer fronts. I had this large piece of olive wood that I purchased a couple years ago from Hearne Hardwoods for just such a project. Olive wood is quite expensive and often very checked (cracked). I schmoozed a single length from the plank to have a matching figure pattern across the 30 inch width of drawers. It came out well. The drawer pulls are also made especially for this cabinet.

The walnut lumber I used came from a tree that grew about two hours from where I live. It was sawn and solar kiln dried by a young man getting started in the career of producing lumber from local trees. The cabinet was finished with waterborne lacquer for a durable and great looking finish. Once the finish had cured I began to package it for UPS shipment to its new home.

The stand is the hardest to pack because it is so fragile. I wrap it with roll foam to protect the finish. I then encase the stand in a box made of 1 inch thick insulating panels to give it a good measure of crush protection. I then put that box into a double walled corrugated carton sealed with reinforced paper tape. The last picture is the two boxes that contain the cabinet and its stand, headed off to the UPS depot.

I received this from the new owner of this cabinet, "...the cabinet arrived yesterday, with no damage. It looks wonderful."

Comments

Post new comment