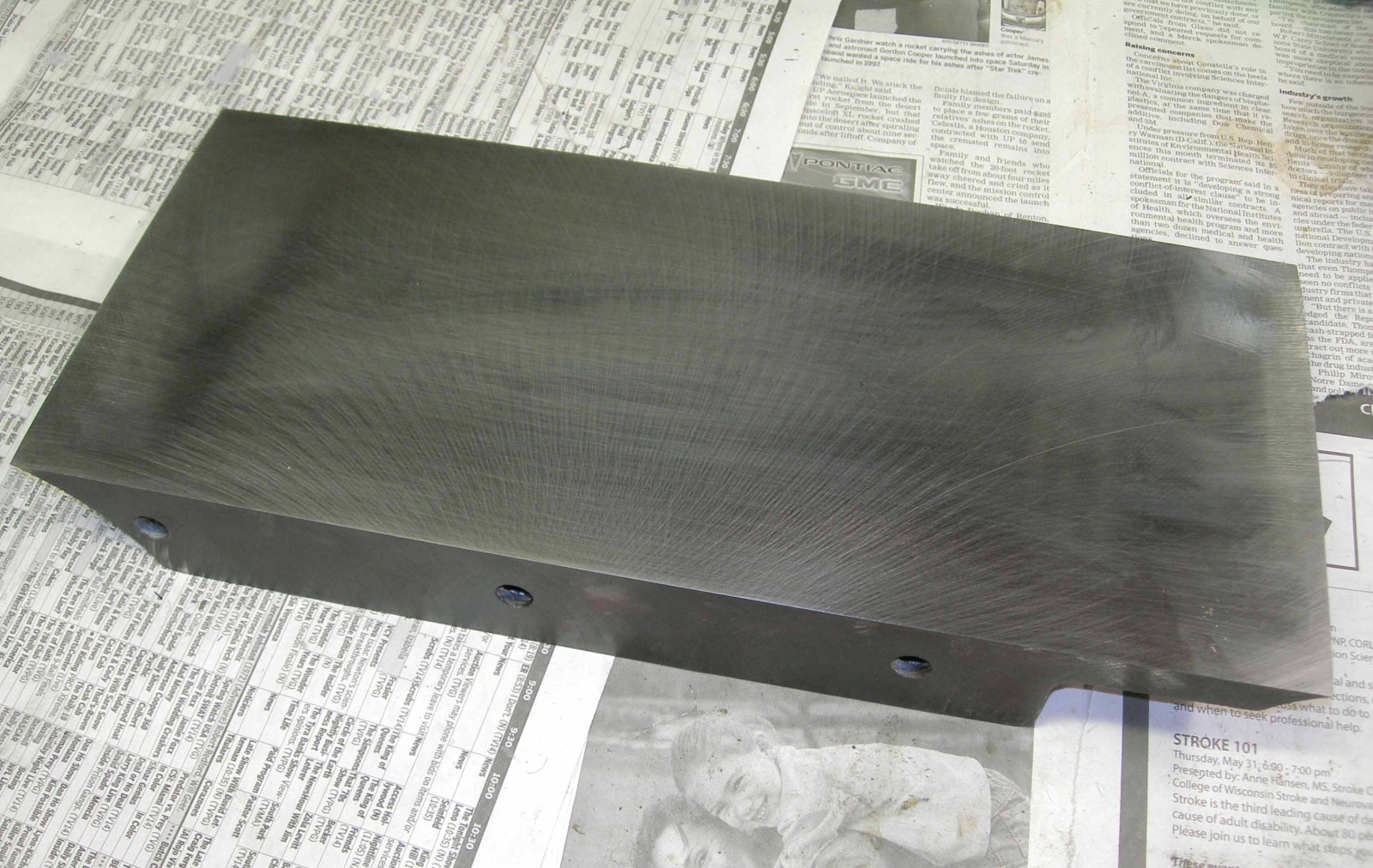

I usually get my graphite canvas from supergrit.com. But it is available from many other places. Googling will find it. I buy the 8 inch width as my 6x48 platens are just over 6 inches wide. That way I have graphite where ever the belt chooses to track. After insuring the platen is true flat and clean, I spray it and the canvas side with 3M™ Hi-Strength 90 Spray Adhesive. Once tacked I place the two together. I have not had it slip, in use, ever. I also do this on my Rigid oscillating belt/spindle sander. On my 4 x 24 belt sanders I replace the metal flap platen with a piece of graphited canvas. This greatly improves the action of that tool. Additionally I use graphited canvas on all my custom shaped platens.

I originally became aware of the use of graphited canvas on sander platens in the late ‘70s. Those were on wide-belt sanders, edge sanders, and stroke sanders.

Comments

Post new comment